- Home

- Skateboard Building

- Double Wide Veneer Pack

Double Wide Veneer Pack

Product Description:

This more-than-double-wide maple stock is suitable for making skimboards, furniture pieces and other projects that require a wider sheet than we carry for skateboards.

These sheets have no splices in them.

This is unusual stock, as it is hard to find logs large enough and clean enough to cut such large expanses of good material.

Double Wide Maple Veneer Pack

- each pack includes 21 Prime or Core grade sheets

- sheet size is 24 x 48 x 1/16”

The 1/16” thickness allows for either flat-sheet or bent-wood laminating.

Handle with care to prevent these large sheets from splitting. If that happens, simply add a bead of glue and press together with masking tape till it dries.

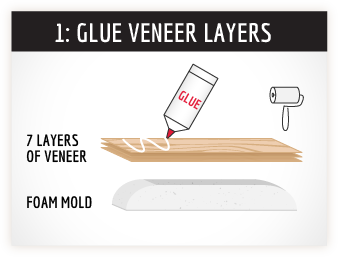

Use Titebond III for most pressings, unless drying time is a major factor.

Although the label on Titebond III says you have 15 minutes before it starts to set, when it is spread out over such a large surface, it will dry much more quickly than that. Use a 9” close-nap paint roller, and extra help to get the glue on quickly. Gluing only a few sheets and pressing at a time is recommended, especially if you are working alone.

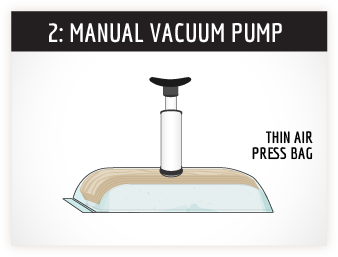

Best Vacuum Bag size: 36 x 52” Thin Air Press TPK36

As noted in the details area, any splits or cracks due to handling can be easily fixed.

Veneer expands and contracts with moisture. Our veneer is shipped with 7-9% humidity. Keep your veneer stored away from heat sources, and lay it flat.

If your work area is very dry, keep your unused veneer sealed in plastic (a garbage will do) until you are ready to use it.

Q: What species is this maple?

A: Acer Saccharum, or Sugar Maple. Other names are Rock, Hard Rock, and Hard Maple.

Q: How long can I store unused veneer for?

A: Very important to store it laying flat and away from any heat sources. Veneer will absorb and release moisture all the time, so seal the veneer in plastic if the environment is changeable.

Q: What if my veneer splits?

A: Run a bead of glue along the split edges. Use masking tape strips to tightly squeeze the edges together and wait about 2 hours for the glue to dry. Remove the tape before using it.

Q: What is the different between the Face, Core and Cross Band sheets?

A: Face sheets are sorted as the clearest layers for the top and bottom of your project. Core sheets are the internal layers, and will have imperfections such as small knots and holes, splits, sap lines and other color variations. Cross grain sheets (also referred to as xbands, or cross bands) have the grain running in the 90˚ direction to the other long grain layers.

Q: Is this Maple harvested from sustainable sources?

A: The mill we source our maple and birch from complies to and is certified by the Sustainable Forestry Initiative® Program, a worldwide recognized service.

Loading... Please wait...

Loading... Please wait...

Canada

Canada